Our Projects

Some activities successfully carried out at a glance.

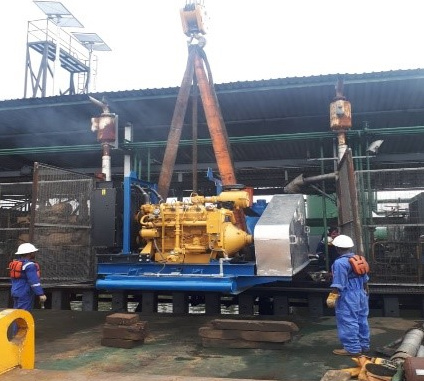

1. Generator & Cylinder Head Work

Re-kitting and servicing of generator cylinder heads to restore full operational capacity. Includes disassembly, component replacement, and precision reassembly.

2. Electric Motor Maintenance

Routine and corrective maintenance of electric motors including bearing replacement, rewinding, and system calibration for optimal performance.

3. Pulsation Dampener Maintenance

Servicing and pressure balancing of pulsation dampeners to stabilize flow and prevent mechanical vibrations during high-pressure operations.

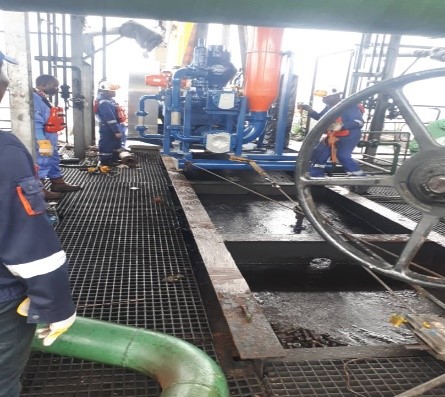

4. Mud Pump Installation & Fabrication

Full-scale installation of industrial mud pumps and on-site fabrication activities supporting field operations and drilling infrastructure.